Accounting for labour cost

Concept of labour costOut of many resources held by an organization, human resources is the most significant one. The success of an organization largely depends on skill and efficiency of person working in it. It is a critical task of the management to manage human resource, which are different in nature and hence difficult to control. Management tries to make the best use of available human resources and minimize the total labour cost by making them more productive. On the other hand, workers may try to earn more by putting lower efforts as much as possible. Due to these contradicting interests, the task of labour management has become more and more difficult in the current days.

Labour cost refers to remuneration paid to the employees in from of wages, salary, and bonus, allowances etc. for their time and effort used in producing goods or services. In other words, monetary resources payable to the employee for their mental and physical sacrifice is called the labour cost. The institute of cost and management accountants (ICMA), London has defined labour cost as "the cost of remuneration of the employees of an undertaking". A significant amount has to be sent to retain the employees in the organization and also to keep them satisfied so that they contribute their best. Labour cost can be analyzed into the following:

Concept of labour costOut of many resources held by an organization, human resources is the most significant one. The success of an organization largely depends on skill and efficiency of person working in it. It is a critical task of the management to manage human resource, which are different in nature and hence difficult to control. Management tries to make the best use of available human resources and minimize the total labour cost by making them more productive. On the other hand, workers may try to earn more by putting lower efforts as much as possible. Due to these contradicting interests, the task of labour management has become more and more difficult in the current days.

Labour cost refers to remuneration paid to the employees in from of wages, salary, and bonus, allowances etc. for their time and effort used in producing goods or services. In other words, monetary resources payable to the employee for their mental and physical sacrifice is called the labour cost. The institute of cost and management accountants (ICMA), London has defined labour cost as "the cost of remuneration of the employees of an undertaking". A significant amount has to be sent to retain the employees in the organization and also to keep them satisfied so that they contribute their best. Labour cost can be analyzed into the following:

a. Monetary benefits: salaries and wages, dearness or other allowances, production incentive or bonus, overtime allowance, provident fund, payment for insurance scheme, old age pension, retirement gratuity, salary in lieu of leave, profit linked bonus etc are the benefits that are provided to the workers in monetary forms.

b. Non-monetary benefits or fringe benefits: subsidized food and housing, subsidized or free transportation, clothing, education to employee's children, medical and recreational facilities etc. are the benefits that are provided to the workers in non-monetary forms.

Types of labour cost

The labour cost can be classified into direct and indirect labour cost as mentioned below:

a. Direct labour cost: direct labour cost is that portion of wages and salaries, which can be identified and charged to a single costing unit. It is the remuneration of the employees who are directly connected with the manufacturing operations or the conversion of raw materials into finished products. The important characteristic of direct labour costs is that, it can be indentified with and allocated to workmen put on definite jobs or products in the factory. Direct labour cost is also known as 'direct wages', 'productive wages', manufacturing wages', 'operating wages', factory wages'. Direct labour cost is a part of the 'prime cost'.

b. Indirect labour cost: indirect labour cost is the remuneration of the employees who are not directly connected with manufacturing operations. The indirect employees are not directly associated with the conversion process but assist in the process by way of supervision, mamintance, transportation of material, materials handling etc. their work benefits all the items being produced and cannot be specifically identified with the individual product. These costs are accumulated and apportioned to different cost centers on equitable basis and absorbed into supervisor, foremen, storekeeper, clerical staff, etc., are the examples of indirect labour costs. Indirect labour cost is also known as 'indirect wages', unproductive wages' and it is treated as a part of overhead.

Differences between direct and indirect labour cost

The differences between the direct and indirect labour costs are mentioned below:

Need of labour cost control

Labour costs may be very high due to inefficiency of about, idle time and unusual overtime, inclusion of d dummy names in the pay rolls and other related factors. Inefficient use of labour not only increases the cost of production but also adversely affects the quality of products. The primary objective of the management, therefore, is to utilize the labour as economically as possible. It is therefore necessary for the management to device a proper system of labour cost control.

Control overlabour costs require proper employment and efficient utilization of labour force. These factors affect the cost and quality of the products of any industrial undertaking and ultimately its profitability. Labour cost control involves employment of efficient workers, proper training of workers, proper time keeping and booking and proper accounting for the wages paid to them.

System of wages payment

The success of a concern largely depends upon the efficiency of labour and the efficiency of labour is considerably affected by the amount of wages paid to them. Some persons are of the view threat the profit of a concern can be maximized only by reducing the wages rates payable to the workers. But this view is not correct. It should be remembered that low-paid workers are usually inefficient leading to wages of materials, costly use of tools, and frequent breakdown of machinery and loss of time as a result of which the cost of production goes up. Reasonable and fear wage rates allowed to the workers ultimately lead to more economic use of machines, tools, materials and time. Therefore, the importance of thee method of wages payment should never be under-estimated.

Method or systems of wages payment must process the following characteristics:

• Simple to operate and easy to understand.

• Guarantee a minimum wage to every worker.

• Acceptable to the employer and the employee.

• Flexible enough so that changes may be made according to the requirements.

• Ensure the establishment of industrial peace.

Piece rate system

In this method, wages are paid to the employees after completions of work. Under it, a worker is paid on the basis of output, not the time taken by worker to perform the work. This is one of the simplest and most commonly used systems of wages payment. In this system, the wages rate is expressed in term of per unit of output, per job or per work-order. The amount of wages payable to a worker under this method is to be calculated as follows:

Total wages = total output x wages rate per unit of output

This system is suitable in the following cases;

• Where a work is of a repetitive nature.

• Where the measurement of work is simple.

• Where the quality and accuracy of output is not very important.

• Where stick supervision is not possible.

Time rate system

Under this system, the amount of remuneration or the total wages payable to the workers depends on the time for which he is employed. This is simple and common method of wages payment. In this method, the worker is paid an hourly, daily, monthly or yearly rate of wages.

Thus the worker is paid on the basis of time and not on his performance or unit of output. The amount of wages payable to a worker under this method is to be calculated as follows:

Total wages = actual time taken x time rate

This method is suitable to be applied in the following circumstances;

• Where the quality of work is more importance than production.

• Where the volume of production is not within the control of labour.

• When it is difficult to fix the unit of output.

• The nature of work is such that there is no basis for incentive plan.

• Where the amount of output cannot be accurately measured, counted and standardized.

Premium plan: incentive wages payment system

Incentive plans have been developed to remove the defects of both time rate and piece rate systems of wages payment. Under these plans, the advantages of time and piece-wages system. Are combined, and incentives are provided to workers to work more efficiently. The characteristics of these are as follows;

a. Incentives by way of bonus and others are given to efficient workers for the time saved.

b. A standard time is fixed and the worker is to perform the given work within the standard time. The standard time is set after making time studies for the performance of specific job.

The incentive is compromise between the two extremities, on the one. If the workers are paid according to time, they gain nothing if time is saved and on the other hand, if they are paid on the basis of piece rate, employers get nothings if time is saved. Under incentive plans, the employer as well as the worker share the benefit of time saved, and both labour and overhead costs are reduced.

The incentive plan should be selected according to the nature of work and other circumstances. It should be accepted by the management as well as labour otherwise it does not functions successfully. The payment of wages may be made according to any of the following plans.

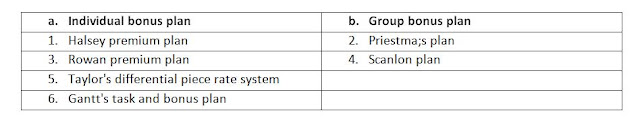

Individual bonus plan

According to individual bonus plan, the bonus of each worker is calculated. Some methods of calculated wages under individual bonus plan are discussed bellow.

a. Halsey premium plan

This plan wages originated by F.A. Halsey this scheme, an hourly rate is guaranteed to all workers. A standard time is fixed for each unit, job or operation on the basis of time and motion studies and the worker is paid the agree hourly rate of wages for the actual time taken plus a fixed percentage of bonus on the time saved. Generally, the amount of bonus or premium payable to the workers is one-half (50%) of the wages of the time saved. However, a company can increase or decrease the rate of bonus.

The following for calculating bonus and total wages/ total earning of the workers under halsey premium plan are:

Basic wages under halsey plan = time rate x standard rate

Advantages of halsey premium plan

The advantages of halsey premium plan are mentioned below.

a. It is simple to understand and operate.

b. Every worker is guaranteed minimum wages and even the inefficient workers feel secured.

c. It encourages efficiency among workers by inducing hem to finish their job before the standard time.

d. The benefit from the time saved is shared equally by the employer and the worker.

e. Generally workers do not oppose this method of wages payment as it rewards time saved rather than increased output.

Disadvantages of Halsey premium plan

The disadvantages of Halsey premium plan are mentioned below.

a. Workers are paid only half of the wages on the time saved. So, the workers may oppose this method.

b. The worker may perform the work in hurry by neglecting the quality of output to save time and earn higher bonus.

c. The standard time fixed for finishing a job not is scientific.

b. Rowan premium plan

This plan was developed by David rowan. This plan guarantees an hourly rate to all workers. A worker is paid the fixed rate per hour for the actual time spent on the job a premium or bonus based on the time saved. The amount of premium or bonus is not a fixed percentage of the wages of the time saved but it various according to the extent of the time saved. The amount of bonus or premium payable under this plan depends on the percentage of time saved by the workers. The bonus is calculating such percentages out of the basis wages.

Basic wages = time taken x standard time rate

Bonus = time saved/ standard time

Total wages = basic wages + bonus

Advantages of rowan premium plan

The advantages of rowan premium plan are mentioned below.

a. This plan guarantees minimum wages and provided incentives for efficiency.

b. It does not induce to rush through worker for increased bonus earning because the bonus increase at a decreasing rate with higher levels of efficiency. Thus, an automatic check for limiting production of inferior quality of goods is earned.

c. The per unit fixed cost decrease with the increase in production

d. Under this method, the per unit cost decrease due to decrease in er unit labour cost.

Disadvantages of rowan premium plan

The disadvantages of rowan premium plan are mentioned below:

1. As the bonus is to be shared by employer and employees, it is not welcomed by employees. They expect full benefit for their extra efficiency.

2. The calculation of earning under this method is comparatively complicated and time consuming.

3. The preparation of labour budget and estimated product labour cost are made difficult by the varying labour costs under this plan.

4. Payment under this plan is much less than that under the Halsey plan by way of bonus below 50% of the time saved.

Comparison between Halsey and rowan plan

• Under both the schemes, basic wage are the same and are guaranteed.

• Both the schemes allow for an incentive 9bonus) to efficient worker. But the amount of bonus payable is different under these schemes.

• When a worker completes his work within half of the time allowed, the bonus under both the plan will be same.

• If time saved is less than 50% of time allowed, the rowan plan is beneficial to the worker.

• If time saved is more than 50% of the standard time, the Halsey plan is advantageous to the worker.

Why rowan plan is better than halsey plan?

• In the halsey plan, bonus is usually set at 50% of the time saved. It does not serve as a strong incentive. One the other hand under the rowan plan, bonus is that proportion of the wages of the time taken which the time saved bears to the standard time; it serve as a strong incentive for increasing the efficiency.

• In the rowan plan, the quality of work is not affected is not affected much. The worker is not induced to rush through the work because bonus increases at a decreasing rate at higher levels of efficiency. In the halsey plan, a worker is induced to rush through the work because he gets extra wages for every for every 50% of the time saved.

• The effective labour rate per hour in the rowan plan is higher upto 50% of the time saved and falls thereafter whereas in the halsey plan, the effective labour rate per hour is lower upto 50% of the time saved and can be double thereafter. Usually, workers are not able to save more than 50% of the time allowed, so workers prefer the rowan plan for earning more wages.

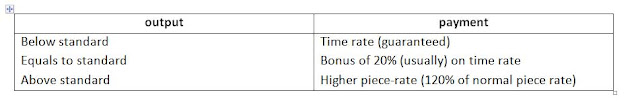

c. Taylor's differential piece rate system

This scheme was developed by F.W. Taylor, who is known as the "father of scientific management." Taylor suggests that the worker producing the below standard level should be paid according to the low price rate. Similarly, the worker producing at or above standard paid according to high piece rate. For this, a standard time is fixed and the worker who finishes the assigned work before the standard time or at standard are paid at a higher rate a d the worker cannot complete the task and motion studies because it demarcates higher and lower rates of wages. Thus, two piece-rate are fixed, one for those who perform the and lower rates of wages. Thus, two piece rates are fixed; one for those who perform less than standard time (may be termed as inefficient workers).

Usually rates are 120% and 80% of the piecework rate for efficient and efficient workers respectively.

Following are the basic requirements for calculating total wages or earning of the workers under Taylor's differential piece rate system:

j. Standard output/ standard yield = time taken x standard output per time unit

k. Standard rate per unit/Normal piece rate = standard wages rate for a period/ standard yield for that period

l. High piece rate for at or above standard = 120% of normal piece rate

m. Low piece rate for below standard = 80% of normal piece rate

Advantages of Taylor's differential piece-rate system

The advantages of Taylor's differential piece-rate system are mentioned below.

a. This system provided a great incentive to workers to achieve the standard output and the slow worker always try to achieve greater efficiency.

b. The system is beneficial to workers as well as employers, since the workers get wages at an increased rate according to units produced and the employers get increased output at lower cost of production.

Disadvantages of Taylor's differential piece-rate system

The disadvantages of Taylor's difference piece-rate system are mentioned below.

i. This system is difficult to apply due to the fixation of different rates.

j. The standard output cannot be justified because if a worker just fails to reach the standard output, the low rate of wages will be given to worker. However, if he just reaches the standard, higher rate of wages will be payable to worker.

k. There is a great different of wages between the higher and lower rates. It creates a large variation in the earning of the workers and conflict may emerge among them.

l. Moreover, employer-employers relation may also be strained, if the standard is put at a very high level.

c. Gantt's task and bonus scheme

This scheme was originated by Mr. Gantt. This scheme is a combination of time rate, differential piece-rate and bonus system and guarantees a minimum time rate. Under this system, minimum wages are guaranteed to workers who fail to reach the standard. If the output of the worker, low rate is not necessary to determine total wages for below standard and if a worker's output is at or above standard, he is paid a higher rate (up to 120% of normal rate) for the actual output.

Following are the basic requirements for calculating total wages/ earning of the worker under Gantt's task and Bonus plan:

a. Standard output/standard yield

b. Standard rate per unit/ normal piece rate / guaranteed piece rate

c. High piece rate for at or above standard, generally 120% of normal piece rate

The remuneration under this method is computer as follows:

Total wages/ earning of the worker for above standard:

= actual yield x high piece rate

Total wages/ earning of the workers for below standard:

= standard yield x normal piece rate

Total wages of worker for at the standard

= (time taken x time rate) + 20% of time wages

Advantages of Gantt's task and bonus scheme

The advantages of Gantt's task and bonus scheme rate mentioned below:

a. This system encourages the worker to improve the level of performance.

b. The workers feel that they are getting the reward, which they are entitled to. Thus, it promotes satisfaction among the employees.

c. This method is very useful in jobs involving engineering activities.

Disadvantages of Gantt's Task and Bonus scheme

The disadvantage of Gantt's task and bonus scheme are mentioned below.

a. Extreme care is to be exercise in fixing the guaranteed time rate and determination of standard output. Any error caused due to lack of experience will lead to unfavorable consequences.

b. If the guaranteed time rate is fixed high, the incentive effect of the plan will deteriorate.

Group Bonus schemes

If the premium plans discussed so far, the bonus payable to an individual was ascertained. Sometimes it is not possible to apply an incentive plan to an individual employs and it may be possible to apply such a plan to the group of employees only. The group bonus system is especially applicable when the workers act in a group as a team. The group incentive plans can be successfully implemented where:

a. Output depends on teamwork and joint efforts of group of workers.

b. It is difficult to measure the individual result rather than the group's result.

c. It is necessary to work as a member of a team rather than on individual basis, e.g. in chemical process industry, an individual worker cannot influence the production of the plant.

d. Both direct and indirect workers need to be compensated equally.

e. Skills of the workers In the group do not vary widely.

Advantages of group bonus scheme

The advantages of group bonus scheme are mentioned below.

a. Increase in production and saving in cost of production can be achieved.

b. Supervision costs will be reduced substantially.

c. The quantity cost will be reduced substantially.

d. Absenteeism is reduced to minimum and creates interest in work among the workers.

e. Routing and scheduling problems are eliminated.

f. It creates team's spirit and reduces cost per unit.

g. Minimum waste and reduces cost per unit.

h. Clerical work in calculation of bonus is reduced.

Disadvantages of group bonus scheme

The disadvantages of group bonus scheme are mentioned below:

a. Individual skill and efficiency are not considered in these systems.

b. Difficulty may arise in calculation of bonus and method of its distribution to all the workers In the group.

c. The bonus is paid on group efforts; and individual worker may not put his maximum effort in vies of equal sharing of bonus to inefficient workers.

d. An inefficient group leader may cause the entire group to suffer.

a. Priestman's plan

Under this system, the standard output and standard time for each department predetermined in consultation with the workers. Bonus is payable to the department when the actual production exceeds the standard production. Where the actual production does not exceed standard, no bonus is paid but time rates are guaranteed. The bonus is calculated as a percentage on such excess production and distributed to all employs in that particulars department by increase their normal wages by the same percentage the actual production increase over the standard.

In this system, the time wages are guaranteed if actual production of the particular division, department, and group is less than the standard output. This method is not only applicable for excess of actual production over the standard but also saving in material and labour costs is considered for payment of bonus. The main drawback in this system is the efficiency of individual worker is not considered and inefficient workers can also claim for bonus.

Bonus rate = increase in actual output/ standard output x 100

Bonus = basic wages x bonus rate

Total wages = basic wages + bonus

b. Scanlon plan

This plan was originanated by joseph Scanlon. It was successfully used in the steel industry in the United States. Under this plan, a constant proportion (the ratio of wages to sales value) of the added value of output is paid to workers, who are jointly responsible for the additions. The added value is measured by change in market value 9including profit0 of a product resulting from a change in form, location or availability of a product or service, excluding the cost of purchase materials or services used in production.

Under this plan, the following steps are used to ascertain the amount of bonus available for distribution:

i. Determine the ratio of actual wages to actual sales = actual wages/ actual sales

j. Then after, determine the ratio of given wages to given sales = given wages/ given sales

k. Make the difference of the above mentioned ratio

l. Calculate the amount of bonus due to the laborers = Given sales x difference in ratio as per step 3

m. Deduct the amount of receive from amount of bonus to the laborers and get the amount of bonus available for distribution.

Labour turnover

Concept of labour turnover

An organization has a perpetual Alexis, but its working force does not remain the same all the time. Some old workers leave the organization and some new workers joint it. This is a natural phenomenon in industrial sector and it gives rise to the problem of labour turnover. Labour turnover can be defined as the rate of changes in the average working force of an organization during a specified period. The word 'change' should be taken to mean separations or accessions, replacements or the average of separations and accessions according to the concept accepted by management. Labour turnover is the rate of displacement of the personnel employed in an organization due to resignation, retirement or retrenchment. If the rate of labour turnover is high, this is a sign of instability of labour and it adversely affects efficiency as well as the profitability of the firm.

The cost of labour increase when the experienced workers go out of the firm and new and inexperienced workers are hired who are to be trained. Therefore, the labour turnover proverbs to be very costly for the business and every effort should be made to reduce the frequency of labour turnover.

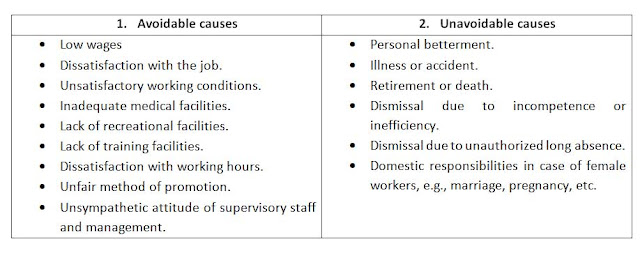

Cause of labour turnover

The main causes of labour turnover can be divided into two categories:

Effects of labour turnover

High labour turnover result in increased cost of production due to the following reasons:

• Interruption in work leading to a decrease in production.

• Cost of selecting new workers.

• Increased cost of training.

• New workers' inefficiency results in less economic use of tools and equipment and nonsuccessive wastage of materials.

• Higher accident rate.

• Overtime wages increase due to an excessive number of separations, causing difficulties in adhering to the delivery dates of the contacts.

Cost of labour turnover

The cost of labour turnover can be divided into two parts:

a. Preventive costs: preventive costs denote the costs, which are incurred to prevent excessive labour turnover by keeping a satistified labour force. These are the costs which are incurred in order to keep the workers satisfied and thus to act as discouragement against leaving employment. These include:

• Cost of personal administration.

• Cost of medical activities.

• Cost of welfare activities.

• Cost of gratuity and pension schemes.

• A portion of high wages, bonus and perquisites.

b. Replacement costs: replacement costs refer to the costs of the recruitment, training and absorption of new workers. These included:

• Cost of recruitment and training of new workers.

• Loss of output due to interruption and inefficiency of new workers.

• Cost of wastage, scrap and defective work.

• Compensation due to frequent accidents.

• Cost of additional supervision.

Preventive and replacement cost calculation

Preventive costs are incurred to keep the workers satisfied and discourage them to lead the organization. They are treated as overhead charges and apportioned to departments on the basis of number of person in respective departments.

Replacement costs aeries on account of labour turnover and consequent replacement of employees. There are two conditions of treatment of replacement costs.

a. The replacement costs should be charged directly to that department if they are caused due to fault of any particular department.

b. They should be charged as part of production overhead and should be apportioned to difference departments on the basis of number of workers in each department.

Treatment of cost labour turnover

The preventive and replacement costs are the costs caused due to labour turnover. Preventive costs should be charged as a works overhead item and apportioned to different departments on the basis of number of workers engaged in each department. Replacement costs should also be treated on the same basis if they arise on account of short sighted policy of the management. However, if they arise on account of the fault a particular department, they should be charged directly to that department.

It is to be noted that labour turnover cannot be completely avoided but its rate can be kept at a considerable low level by taking such steps which improved morals and create a congenial atmospheres in the organization.

Control and minimization of labour turnover

Labour turnover can be minimized by taking following steps:

a. Right job for the right man: this is the most significant aspect on which the management should concentrate. Every worker is not fit to handle every type of jobs. If a worker is placed as per the qualifications and the attitude of the person concerned problems are likely occur.

b. Farsightedness: management should be also think of requirements of the future. In the short run, it may have to incur more expenditure on providing amenities to work.

c. Direct contact: there should be a straight and continues dialogue between the workers and management. It leads to disclosure of worker's problems and their psychology. As a result, the problems can be sorted out by negotiations across the table.

d. Standardization of systems and procedures: all systems and procedures regarding selection, training, use of labour force etc. should be standardized scientifically. Properly laid down rules and regulations results in less conflict.

e. Proper implementation of scientific systems with flexibility: a proper and objective system of implementing the labour rules and regulations should be developed. The management has to deal with human beings with the human approach.

Labour turnover ratios

Labour turnover may be measured by any of the following method. The choice of a particular method depends on whether emphasis is given on labour separations, replacements or both, but once a particular method is chosen, it should be adopted consistently so that comparison may be possible.

a. Separation rate method: this is the most commonly used method. This method takes into consideration the number of workers left or discharged during the period. Labour turnover is determined by dividing the total number of separations during the month/year by the average number of workers employed during the month/year and multiplying that by 100.

Labour turnover = No. of workers separate during the period / average no. of workers during the period x 100

b. Replacement rate method: this method takes into consideration the number of workers replaced during the period irrespective of the number of workers left or discharged. Dividing the number of workers replaced during the month/ year by the average number of workers employed during the month/year and multiplying that by 100 determine labour turnover.

Labour turnover = No. of workers replaced during the period/ average number of workers during the period x 100

c. Labour flux rate method: this method takes into consideration both the number of workers left or discharged and the number of workers replaced during the period. Thus, this method it the combination of the previous of two method. The formula for calculation labour turnover under this method is as follows:

Labour turnover = during of period + during the period/ average no. of workers during the period x 100

d. Equivalent annual rate of labour turnover: in case it is decided to relate the labour turnover rate for a month or fraction of a month to annual rate of turnover, this may be done by finding out "equivalent annual rate" with the help of the following formula:

Equivalent annual rate = turnover rate x 365/ No. of days in the relevant period x 100

Hi,

ReplyDeleteI have read your blog very carefully. The information you provide is very helpful. I also provide same services.

Thanks for sharing this useful blog.

Please visit MJS Accounting for more details

This comment has been removed by the author.

ReplyDelete“Good insights! For businesses that want to stay penalty-free, Digiliance’s Contract Labour Compliance Services are a must-have.”

ReplyDelete